DVT review and computex

June 14, 2024

Calder

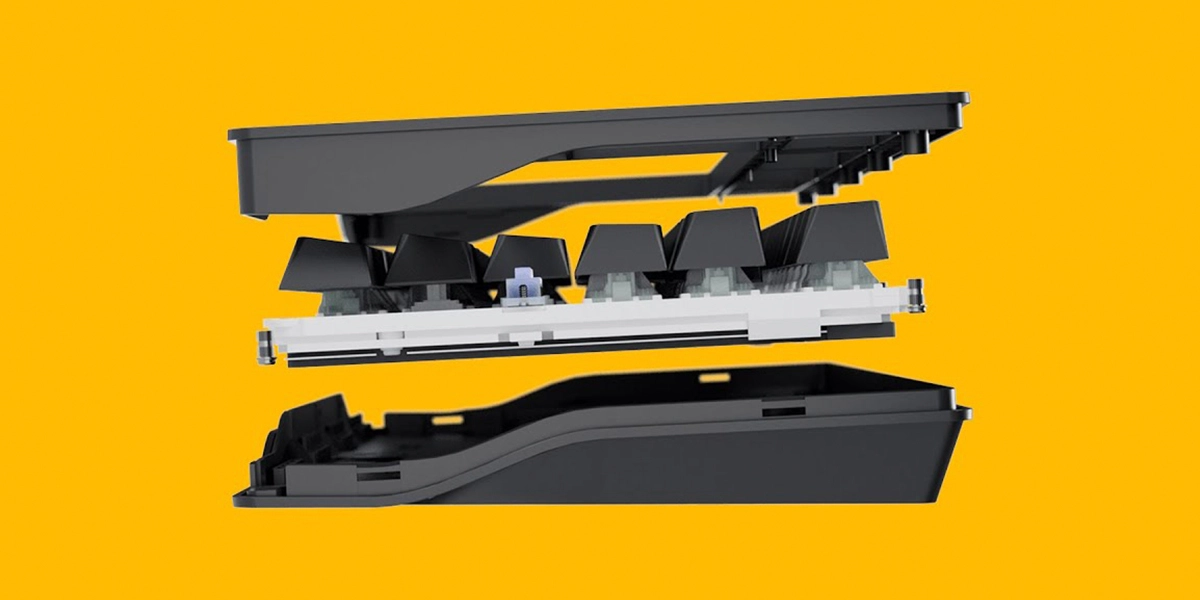

Calder, Kevin and Vanessa visited the factory where our keyboards are being produced. We’re edging closer to the final version of the 80HE and needed to confirm a couple of samples regarding the RAW case and packaging. Official production will start soon!

The Zinc Alloy RAW case

The RAW case has been somewhat of a challenge to get exactly right and we’ve been trying out a lot of different finishes to see what fits best. The biggest challenge was that the case would have watermarks on there after passivation, that were impossible to wipe off and feels like blemish. During the factory visit we could look at samples ourselves and try to think of a way to avoid getting watermarks on the cases.

This resulted in us ditching a process called ‘bluing’. This process provides the metal with some corrosion resistance and adds a slight blue-ish glow to the metal. But to avoid the watermarks, we went for a different approach, lengthening the passivation process and skipping the bluing process. The results were amazing, with no watermarks and a truly RAW case.

Testing the RAW case in the factory

Now that we’ve found our finish, the RAW case will undergo a so-called ‘salt bath test’. During this test the case is exposed to salt and water in a controlled environment, to see how durable the material really is. If all goes well we’ll be really close to our ‘golden sample’ that will function as an example of how a case should look when it comes out of the factory.

Long story short: RAW case, almost final checkmarked!

LED bar update

We’ve got a small update on the LED bar development. We’ve been searching for a suitable ‘dark’ LED bar that will be used in all the dark 80HE cases. We almost gave up on this because we just couldn’t get it right, but the last samples we received look promising.

© 2015 - 2025 Wooting B.V. All rights reserved.