ABS vs PBT - What are the best keycaps?

July 6, 2021

Henry

When shopping for keycaps there’s a lot of options regarding materials, layouts, profiles, and colors. It can be difficult to navigate through the internet to find which keycaps are best for you, especially when you don’t understand the lingo. The best keycap for your keyboard isn’t necessarily made of ABS or PBT either. Even if you are to find your desired keycap style, are these keycaps compatible with your own keyboard?

This is the complete breakdown that you will need to know in search of the best keycap for you.

Keycap Material

Keycaps are generally made from two different types of plastic— PBT or ABS. PBT (Polybutylene Terephthalate) is a stronger and thicker plastic. ABS (Acrylonitrile Butadiene Styrene) is a versatile, affordable plastic used more often.

PBT keycaps are of higher quality than ABS keycaps, thanks to their better material properties. This is not true by default. A keycap manufacturer can make poor quality PBT keycaps and great quality ABS keycaps. This depends on the production method, thickness, design, and material composition. PBT keycaps are rarely 100% made of PBT. It’s often mixed with other materials, such as glass fiber, to make it easier to put into production.

Thanks to ABS’s great material properties, these allow purer variations, better character-, color design, and price. This isn’t to say that they're always the cheapest. GMK is a high quality custom keycap manufacturer that only produces ABS keycaps. They are expensive keycaps and high in demand within the keyboard community.

PBT Pros:

- High quality

- Excellent durability

- Deep sound signature

- No keycap shine

- Higher melting point than ABS (225°F/107°C)

PBT Cons:

- Expensive

- Lacking in design options

- Harder to manufacture, PBT is also harder to control

- Keycap warping

ABS Pros:

- Smooth texture

- Economic

- Easy to manufacture, will produce consistent results with ABS

- High pitched sound signature

- Vast amount of design options

ABS Cons:

- Cheaper quality

- Develops keycap shine

- Often thinner keycaps

- Lower melting point than PBT (105°F/~40.5°C)

It doesn’t end with just PBT or ABS. There are a variety of other materials used to make keycaps, but are very niche, such as POM, PPS, and even artisan novelty keycaps.

POM (Polyoxymethylene) is a smooth, but also very durable keycap. They have a soft, but higher pitched sound signature. The legends are often laser engraved (if at all) which can fade over time. Jelly keycaps are currently the most popular POM set on the market. These give a milky and smooth look to the keycap.

PPS (Polyphenylene Sulfide) keycaps are heavy and expensive due to their rarity. They come with a very deep sound signature and can withstand more abrasion, higher temperatures, and chemicals than the high quality PBT keycaps. These keycaps are incapable of being manufactured with dye-sub and laser-etching, so most of these keycaps do not come with legends. Additionally, PPS keycaps are prone to scratches on its surface and are brittle.

Novelty keycaps serve the sole purpose of being decorative to your keyboard. These keycaps can be made with any of the most commonly used materials and adds aesthetic to your keyboard. A popular branch of Novelty keycaps are Artisan keycaps, which are often resin based keycaps made by individual artisans by hand.

Keycap Legends

Keycaps have a wide range of manufacturing methods that affect the keycaps’ texture, quality, color, and legend.

- Doubleshot: Combines two plastic injections into a single keycap. The first injection is for the keycap legend, the second is for the keycap housing. This has various different production methods but always results in the longest lasting legends. This method is frequently used with ABS and PBT keycaps. This supports backlit keys if the legend plastic is a transparent or opaque milky material.

- Painted Laser Etching: This method is used for color painted ABS keycaps with laser etched legends and then cured with a varnish-type finish using UV light for durability. This is used for ABS backlit keycaps and often found on RGB backlit keyboards.

- Dye-sublimation: The keycap legend is a dye that is submerged into the plastic keycap using heat. Additionally, there is inverse dye-sublimation which is very similar to dye-sub, but instead of the legend, the keycap is dyed around the legend. Dye-sub is used on PBT keycaps, since ABS can’t withstand the heat from this process. This does not support backlit keys.

- Laser Etching: The legends are (laser) etched into the keycap. This will result in a charcoal colored legend. It’s also possible to have it filled with white dye. This does not support backlit keys.

- Pad printing: The legend is ink pressed onto the keycap. It results in a slightly raised (tactile) legend. This is the cheapest method and also has poor durability. This does not support backlit keys.

At Wooting, we use ABS UV printed keycaps, double-shot PBT keycaps, and in some occasions dye-sublimated PBT keycaps.

Keycap Profiles

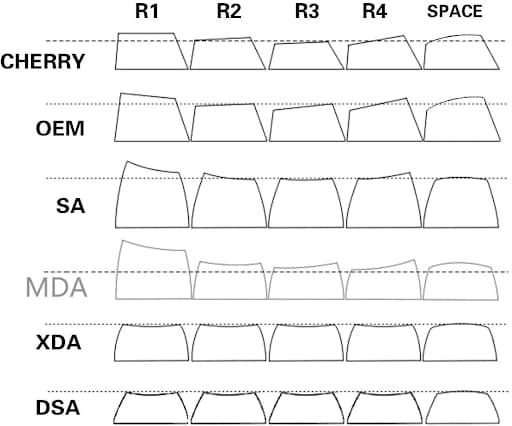

The keycap profile is a reference to the keycap’s shape; typically its height and the small nuances that come with the varying profiles.

All profiles are either sculpted or uniform. Sculpted keycaps are when the height and angle vary from row to row. Whereas uniform keycaps hold the same shape throughout the entire keyboard.

Common profiles include:

- OEM: A commonly used profile. This profile is sculpted and used industry-wide.

- Cherry: Sculpted and has grown in popularity. These are similar to the OEM profile but are lower in height and have a sharp, angular look to it.

- SA: Sculpted and vintage. This is the tallest keycap profile. It was widely used for keyboards in the 80s and 90s, but has made its comeback to modern keyboards for being stylish and comfortable for typing.

- DSA: Uniform and low profiled. These are low, flat keycaps that allow the keycaps to be swapped around easily thanks to its uniform profile. These are often used on non-angled keyboards.

- Novelty: This profile doesn’t have a particular set of “rules”. They can be sculpted or uniform, and have simple legends or sophisticated art displayed on them.

These are the typical keycap profiles used on keyboards. There are a lot of similar profile variations, such as XDA being similar to DSA and MDS to SA, that are all unique in look and feel.

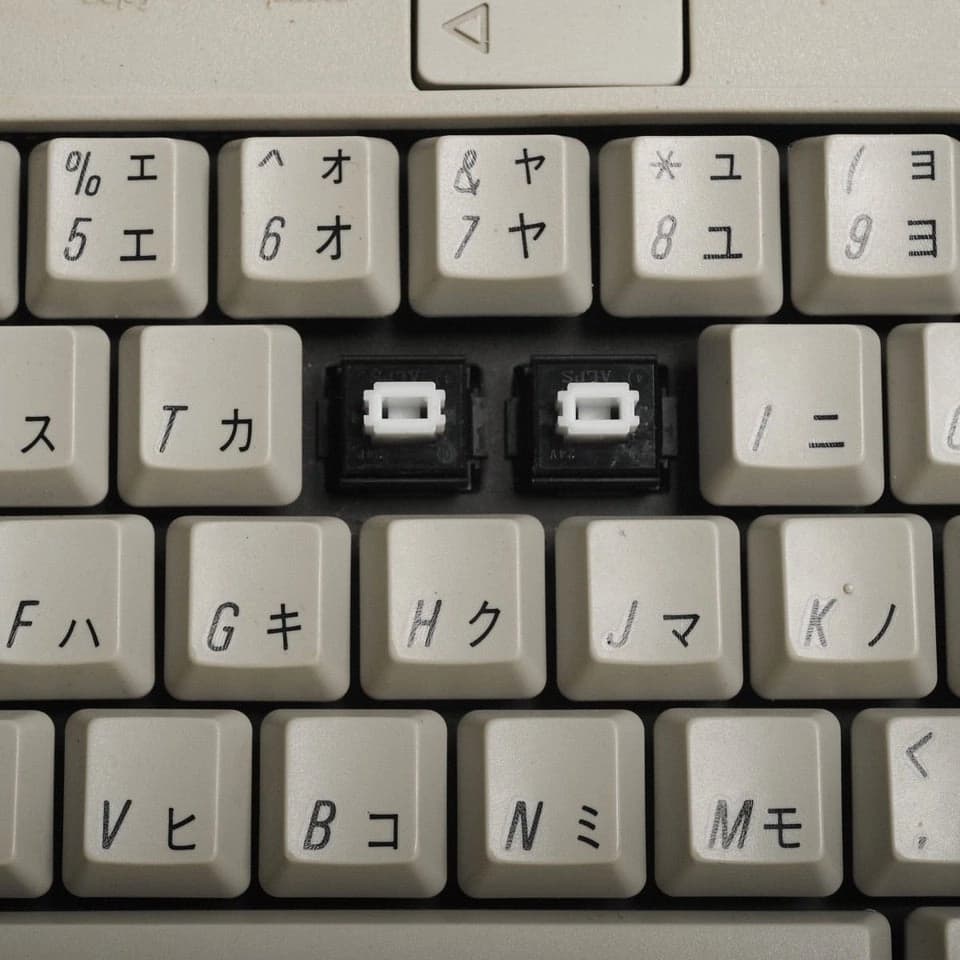

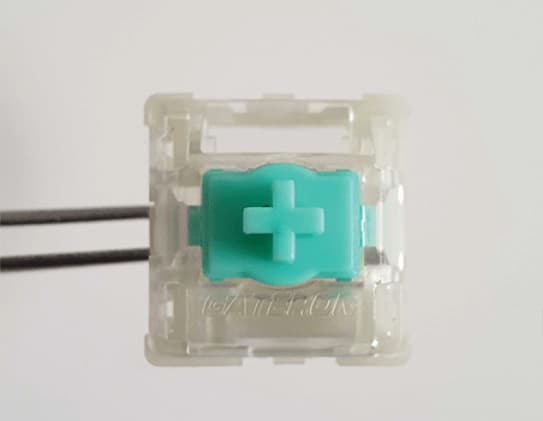

Mount Compatibility

The mounting style of keycaps refers to the keycap stems being compatible with the switches. The most common switch stems are the Cherry MX stems, containing the common cross-shaped stem compatible with many different keycaps. Additionally, there are also Alps and Topre switches that have their own unique mounting system and are not compatible with the more popular Cherry MX stems. It is possible to find a switch-stem adapter for Topre switches to also fit MX stem keycaps.

Keyboard Layout

In addition to all the different profiles and methods of producing keycaps, there is a range of sizes of the keyboards that can affect which keycaps you use or purchase.

The most important difference is ANSI versus ISO.

ANSI is the most popular layout and has the most compatibility with keycaps on the market. Regardless of the country, ANSI keycaps often have US English legends in addition to the localized language legends. It has 1 key less in comparison to ISO, a rectangular shaped return/enter key, and large left shift.

ISO is less popular but the default layout in European countries. Among the ISO layout there’re a lot of language variations with vastly different legends. This also makes it difficult to find a keycap set in an ISO layout with localized language legends. It has 1 additional key in comparison to ANSI, a mirror L shape return/enter key, and smaller left shift.

Full Size / 100% layout

Full-sized keyboards are the most widely known keyboard size to the average person. They are typically found in offices since it comes with a number pad, making data entry easier. The keycaps for a full-sized keyboard are the typical standard keycap units shared across most of the layouts.

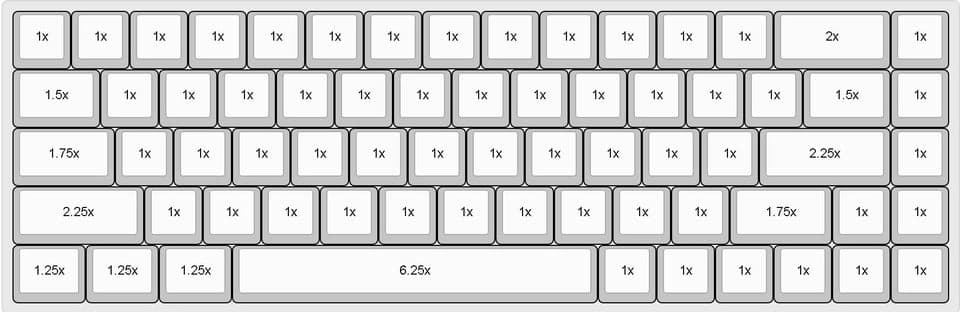

60% Layout

60% keyboards are popular within the gaming community thanks to its smaller, more compact size. A cookie-cutter 60% layout uses all the standard layout keycaps. There are variations that include a smaller right shift keycap, or 1 unit modifier keys. These are uncommon keycap sizes that you’ll more frequently find on 65 or 75% keyboards.

65% / 75% layout

The 65/75% keyboards often follow a unique layout that require different sized keycaps. This is because the layout is essentially “squishing” the arrow keys and other navigation keys next to the alpha and modifier keys. You need to be careful when looking for 65/75% layout keycaps.

Often the right shift is a 1.75 unit instead of the standard 2.75 unit key. Moreover, depending on the variation, the right side modifier keys (alt, fn, ctrl) are 1 unit instead of the standard 1.25 unit keys. To further complicate the issue, if it’s a sculpted profile, you can’t simply use other keycaps from a different row. It’s uncommon to find these specific rows’ 1 and 1.75 unit keys in standard keycap sets.

The take away

Keycaps can be made in a variety of ways, with a variety of plastics, that can affect how the keycap feels. Quality ABS or PBT double-shot keycaps are a solid choice, especially if you want shine-through/backlit keys. Otherwise, there is a rich choice of PBT dye-sub keycaps that are a great alternative. In addition to the material, the keycap’s profile influences the feel and aesthetic of the keyboard as well. However, when building your own keyboard, you should be aware of the different sizes and layouts so you can appropriately purchase the correct keycaps.

From Wooting.

With love.

Product updates, news, and launches.

Help & Account

Company

© 2015 - 2026 Wooting. All rights reserved.