Sailing the Lekker boat | Lekker update #4

April 14, 2020

Calder

Hi Backers,

As captain of this ship, I want to make sure we can sail our boat through these heavy weathers without making hasty decisions. Confidence, security, and trust play a vital role. A big part of that is sharing the information I have at hand and let you know what lies ahead. Regardless of a positive or negative weather forecast. Transparency in communication is key.

The COVID-19 has shown its teeth. Thankfully, the impact is not widespread on our business and it’s for the most part impacting our project progress and logistics. When it comes to the sales and day-to-day operations at Wooting, we’re blessed with favorable winds.

At Wooting we already operate entirely remotely, have barely any employees and have a very low monthly fixed cost. This means that we can last longer with less. We are all working from home, safe and healthy from either Taiwan or The Netherlands. Wooting is running expected or more revenue than forecasted and we already had a cash reserve saved up to grow the business.

When it comes to logistics, we’re getting more last-mile shipping issues in the USA, few shipping restrictions in Europe and overall slightly longer delivery times. We’re not able to quickly get our hands on new stock, but thankfully we have our distributing partner, Seasonic, to provide buffers throughout this period.

In the USA, there’s a bit of unfortunate timing with our 3PL. They got bought out by another 3PL company. They’re moving quickly and there’s a bit lack of clear information, but until so far it hasn’t impacted the day-to-day shipments. It has impacted checking in more stock and is causing temporarily out-of-stock backorders in the US for Wooting one and two.

Now to focus more specifically on the Lekker Edition project. This is where we are hit with significant slowdowns, covering 3 topics:

- We decided to work with a different assembly factory (Medium)

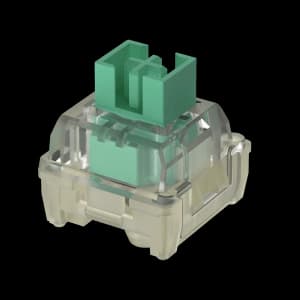

- The Lekker switch is pending final tooling (High)

- Worldwide logistics has significantly slowed down (High)

I have to give an advanced notice that I can’t share too many details and plans publicly until after the facts. Publishing this type of information can potentially harm or influence our negotiations and/or our supplier relationships.

Assembly factory

We decided to produce the Wooting two Lekker Edition with a different assembly factory and are finalizing the details. This was something we were already planning to do, but we hadn’t made the final decision yet. Using a different assembly factory is not a small feat, and requires careful consideration.

We have always worked with a single assembly factory for the Wooting one and two keyboards but looking at the future we want to expand our roots, knowledge, and experience. If we continue to make all our keyboards with the same assembly factory we will start creating tunnel vision and rely too much on their capabilities.

The assembly factory we’ve worked with until so far has taught us a great deal was always welcoming and have always been supportive. The decision to start with a new assembly factory, therefore, comes with a few fears, but over the long term will do Wooting a lot of good. It’ll help boost our internal assets (knowledge/experience) and increase our negotiation capabilities (more choice in suppliers). This will be key once we need to quickly scale our production and spread our risks.

Wooting doesn’t only capture our passion, vision and provide two slices of bread on the table. It’s also a learning vessel for us. Through Wooting we’ve all gained an immense amount of experience, knowledge, and insight. We experiment, take risks and learn every step of the way. And these are elements worth more than simply profits. They provide a solid basis for Wooting as a whole and help us create a company culture that places focus on people as assets.

Vetting for a new factory takes a long time for us because we can’t work with just any manufacturer. We don’t make ordinary keyboards and we’re fairly critical with the process. We had already orientated ourselves for a while and are confident that this new assembly factory has the capabilities we require and understands Wooting’s underlying value.

We wouldn’t have made this decision if we believed that it would severely impact the project and cause a major delay at this stage. We’ve given this a lot of thought and time but held off with the final decision until we were ready.

Switch factory

We had approved the final switch samples and drawings. Now it’s all about making the final mold/tooling, something we had originally wanted to be done by now. This is where COVID-19 has the greatest impact on making progress.

The switch factory is weathering a heavy storm. The COVID-19 lockdown had kept a lot of their employees in their home town (after celebrating Chinese New Year with family), creating a backlog in their production. Unfortunately, the employees responsible for tooling/molds were stuck in the Hubei area, where COVID-19 struck the hardest and the lockdown was most vigorous.

Now that China is slowly relaxing its regulations, they were able to return to Guangzhou (factory area). This in itself already severely impacted our schedule, but now it’s still not over. The switch factory has decided to prioritize other clients over us until further notice. Our project requires the opening of a new mold/tooling and changes to an assembly machine, something that costs significant man-hours that they can’t afford at this moment.

I was asked to use the first generation (gen1) Lekker switches to avoid further delay, an option, but honestly, not ideal. We set out to do something and want the best for our product. Using the gen1 switches is simply a step back and not ideal if we look at the long term.

I’m pushing for a new production schedule and trying to get more information on what we can expect. I dislike waiting and depending on a single party. And this is not the first time. That’s why, in the meanwhile, we’re looking at alternative solutions.

What is vital here is that we need to make the Wooting two Lekker Edition keyboard with the quality and analog performance that we expect from it. The Lekker Edition project is a vessel that has to carry us to the next phase in our overall goal (standardize analog input) and further build/grow Wooting.

I’m confident we’re able to overcome these challenges and regardless of how things pan out, we have something in motion that should ensure we can deliver on our promises.

Logistical slowdown

The COVID-19 virus has an enormous impact on Airfreight. There’s a lot less to no commercial flights that usually also carry cargo inside and there’s a high urgency for medical supplies. The spike in demand and the depletion in supply equals ridiculous prices until it stabilizes. It’s uncertain for now how things will pan out, but it’s financially unreasonable now to pay the additional cost for faster transport. Something that we’ve always done with previous projects.

This means that we can only use Sea and perhaps Train (EU) freight. These are both also experiencing slower movement due to longer export and import processes, depending on the country. I can’t say exactly what to expect at this very moment until I start asking for quotes. But it’s safe to assume that this will in all cases delay the project by 2 months.

Any benefit?

We grab every opportunity to improve the product from its original design. It started with PCBA improvements, switch design, the cable and recently we added the Snackbar - PBT dye-sub spacebar as a gift inside every Wooting two Lekker Edition.

Now we have another opportunity that we’re using to make further improvements to the PCBA and software development.

PCBA improvements

The following is a bit of a layman’s explanation.

When Jeroen made the initial PCBA design for the Lekker switch, it was, for the most part, a copy of our Flaretech switch design. This worked great for proof of concept, but Jeroen quickly noticed there was a lot of space for improvement.

The new technology allowed us to remove a few costly components, Jeroen explored this route but in the end, it came at the cost of reading speed, a compromise we were not willing to make. (Lekker update #2). We ended up with a PCBA that was similar to our original design with a few improvements to filter noise and increase signal resolution.

Now that we’ve used this PCBA for a while, Jeroen has found a couple of methods that might allow us to further increase the signal resolution. This would mean more precise granular control. We’re grabbing the opportunity to explore this route without risking the entire project.

It’s always worth the time and risk to explore a better PCBA design. The rule of thumb for us is: the better we make the hardware, the less we need to compensate in software. This is in most cases better for performance and prevents the lazy-man's solution: We’ll fix it in post.

Software development

Jeroen, Simon, and Erik have spent a good amount of time on the Wootility lately for the full programmability update. This was partially thanks to the delayed delivery. We hope to round this up into the open Beta release soon, now that the focus is shifting back on software development for the Lekker Edition.

All software development for the Lekker Edition is focused on fundamental areas first.

- Analog signal testing and quality control during MP

- Passive/manual analog input calibration

- Implementation of a larger analog range in Wootility and broader tweaking capabilities.

- The additional (16MB!) memory, and how this is represented in the Wootility (profiles).

- Implementation of Rapid trigger in the Wootility.

At this moment, the Wooting two Lekker Edition works exactly the same as a Wooting two with the added bonus of Rapid trigger and a larger analog range. Without any tweaking or optimizing. Good for testing, but not good enough for the final.

Once we’ve rounded the fundamentals, we can start working on more features. There’s a long list. We’re starting with features that are fast to implement and have high impact. Other than what was described above, think of:

- Per key actuation points

- Multiple analog curves

- More keycap profiles and/or layers

- Enhanced RGB (effects)

- Input velocity beta

If you’re reading this as a current Wooting one/two owner, the software work described above will be translated into a simplified form for your current (Flaretech) keyboard. The limitation is analog range and memory. We want to also implement for example per-key actuation on Flaretech keyboards, but you might be limited to 1 profile.

Limited amount

Lastly, as the Lekker Edition project is taking longer, less of them are available. We set a limit to 1000 pieces and at the time of writing, there are only 250 pieces left. Once this reaches 0, it’s not available anymore. That’s all the Lekker Editions we will make. And as a Lekker Edition owner, you’ll receive the best deal, receive it at the earliest date and have the most unique analog input keyboard ever made 😅. Especially since we're also** not producing/selling the Keycap set **separate anymore either.

What’s the new timeline

I don’t want to start claiming that it’s all the fault of COVID-19. The communication and working speed with the switch factory already wasn’t the fastest, and if things followed our original schedule, then we’d be ahead of the COVID-19 issues. If anything, the virus has placed an exclamation mark at places where we need to pay extra attention and take more aggressive decisions.

We need to collectively move forward with confidence and patience. This is definitely not going to take another year, think months instead. But in this update, I’m reluctant to set a new date and want to keep it an open-end until the May update #5. That’s when I have more information to work with and we will have completed a lot of the things that are now in motion.

Don’t fixate yourself on a date, keep in mind that this is a project we’re all in together and know that we appreciate the hell out of you all supporting us. Hopefully, you can join us in the next Wooting livestream this Friday (17 April 15:00 GMT+2), I invite you to ask questions and share your thoughts.

As a final note,

There's this semi-final Wooting two Lekker Edition keyboard in my office that is laughing at me on a daily basis. It houses the hot-swappable sample switches, final- plate and bottom color, and keycaps. It's fully functional with early software caveats and what I used to make the Rapid trigger video. It's frustrating to be so close yet so far away at the same time. But at the same time it boosts my confidence that the product is not the problem. It's exactly what I imagined when we started the Wooting journey and it opens an entire new space of possibilities. It's going to blow your mind, take my word for it.

<3,Calder

Join the discussion below

We’re sailing through heavy weathers, but the Lekker boat is sturdy and sails forward with confidence. Read the latest Lekker Update #4. pic.twitter.com/ZNQ29RkExI

— WootingKB (@WootingKB) April 14, 2020

© 2015 - 2025 Wooting technologies版权所有。