How to silence and sound-dampen your mechanical keyboard

July 22, 2021

Lili

For some people moving from rubber dome keyboards, the noise associated comes as a surprise. The plastic-on-plastic nature of the moving parts involved in a mechanical keyboard switch create more clicking and clacking noises than a rubber dome keyboard. For some, this is part of the enjoyment of mechanical keyboards - for others, not so much.

If you're one to mind the loud clackety-clack of mechanical keyboards, this article will cover ways to silence and sound-dampen your mechanical keyboard and regain control of your auditory experience.

What makes a mechanical keyboard clack

- Switch movement and mounting system

- Keycap material

- Case material, resonance, and build

- Vibration transfer to the table

How to silence a mechanical keyboard

- O-rings, landing pads or clips for the switch

- Thicker keycaps with less resonance

- Lubricating the switches, band-aid clip mod the stabilizers

- Custom case or case dampening; bitumen and foam

- Deskmats under the keyboard

Why are mechanical keyboards so loud?

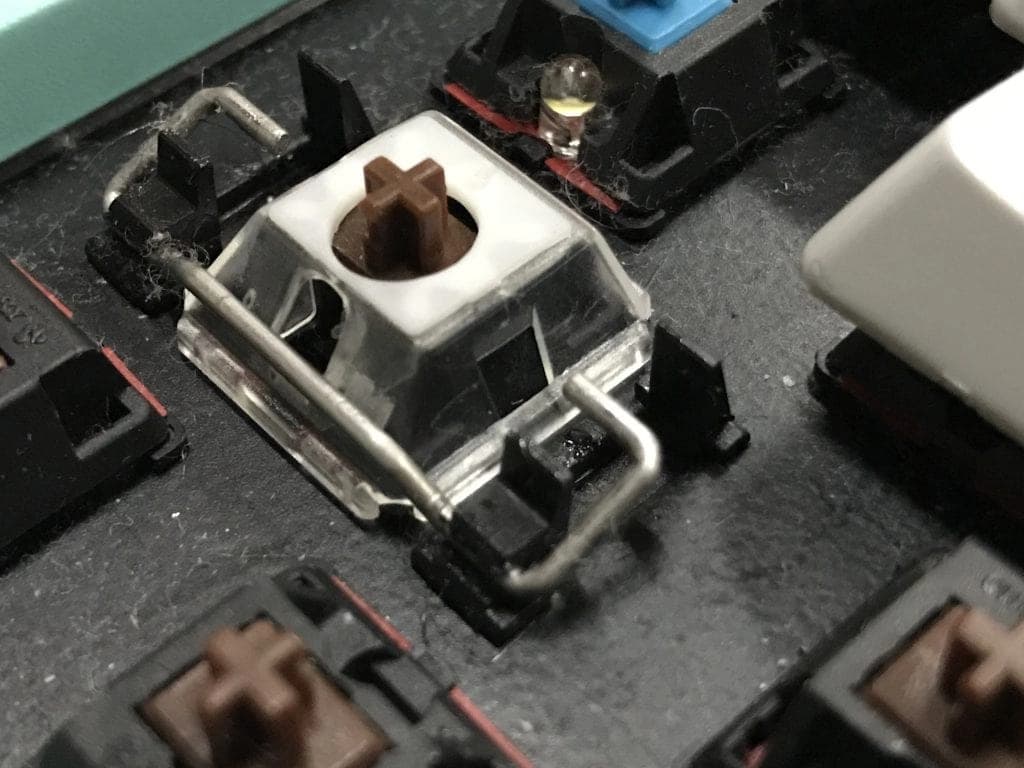

Switches

Mechanical switches have a stem that moves up and down, with a spring inside that returns the switch to its resting position. This movement of the plastic stem inside against the plastic housing creates scraping sounds. In addition, when each switch is released from depression, it shoots back up hitting the upper housing of the switch.

Some switches, like the clicky Cherry MX Blue for example, have a click jacket inside that is responsible for creating the clicking sounds. This jacket is put under tension and released at the actuation point, slamming it against the bottom housing.

How the switch is mounted to the keyboard also affects the sound signature. Keyboards almost always come with a switch plate to which the switches clicked on before being soldered onto the circuit board (PCB) or installed in a switch socket. Older keyboards didn't necessarily have switch plates, resulting in a "softer" feeling keypress as the circuit board flexes a little under every keypress. This flexible nature also affects the sound signature in different ways.

Depending on how the keyboard is built, vibrations can travel through the plate and reverberate inside the case, but more on that later. Just know that while a plate provides stability, weight and aesthetics, it also affects how sound travels throughout the keyboard chassis.

Keycaps

After switches, the next thing to influence your auditory experience is the keycaps. As the switches are pressed in, their travel is stopped by the keycap hitting the top of the switch housing. This produces different kinds of sounds, depending on the keycap thickness and material.

Thicker keycaps are often 1.3-1.5mm thick, sometimes even more, compared to default keycaps that are less than 1mm thick. A thicker keycap will result in a lower frequency “clack” sound, while a thinner keycap will have a higher frequency “click” sound. A lower-frequency "clack" instead of a high-pitched "click" is by often regarded as more pleasing to the ear, even if the overall dB volume is equal.

You can find a flora of different keycap materials online. Some examples, plastics (ABS, PBT, POM, and Nylon), metals (aluminum, zinc, copper), and silicone. Each will produce a completely different sound signature based on how sensitive it is to vibrations and sound penetration.

ABS and PBT plastic keycaps dominate the market, with PBT plastic being the preferred choice. PBT keycaps often result in a lower frequency, ABS keycaps in a higher frequency, depending on the material composition. PBT keycaps are often mixed with glass fiber to increase its adherence to other plastics used for the keycap characters, to lower cost, and decrease defect rate. If the glass fiber mixture is high, it’ll not be easily distinguishable from an ABS keycap.

Keyboard Case

The case is a hidden enemy to the keyboard sound signature. Depending on how the keyboard case or chassis is built, sound can reverberate inside and amplify the sounds created by the components listed above. This ranges from the mechanical structure to the number of screws used. A hollow space inside the keyboard can create an echo chamber and every screw in a plate will impact the vibrations surrounding each key, creating non-uniform sound signatures.

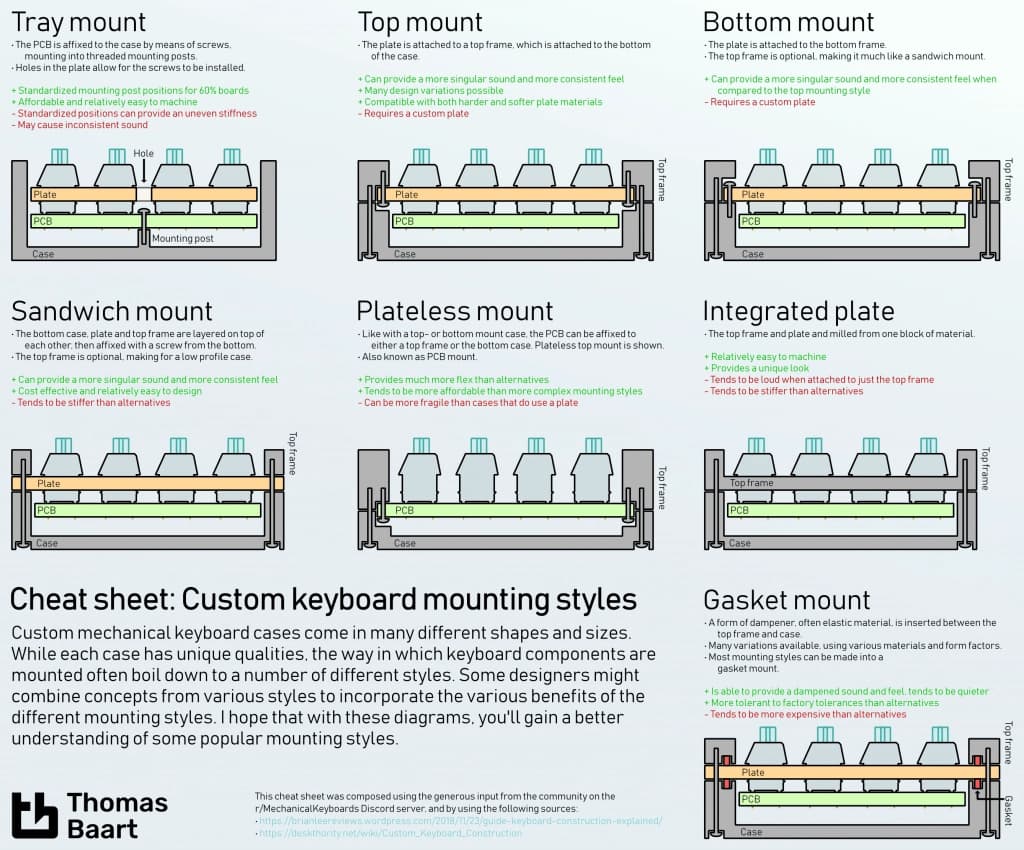

This is why the case assembly method plays an important role. There’s sandwich mount, tray mount, and gasket mount to name a few. When you look at major brand keyboards, these are screw-in mounts. The switch plate and PCBA is screwed on to the bottom case.

In addition, the material and heft play a big role in the case's sound output. An aluminum CNC-machined case with thick walls reverberates less than a thin plastic housing where the parts can flex around.

Table

Lastly, an unexpected enemy - your table. A hollow wooden table will pick up the vibrations from your keypresses and contribute to the sounds of typing.

Similarly, an aesthetically pleasing glass table will sometimes add an uncomfortable metallic tinge to the sound signature. On the contrary however, a thick, solid wooden top with a robust construction will add barely anything to the sound.

How to silence a mechanical keyboard

Depending on how silent you want your experience to be, you need to tackle one or more of the parts causing the sound. Some are easier to eliminate, others more difficult. It will all depend on how much sound you personally tolerate.

Silencing switches and keycaps

This one is easy and often the first step people take. To lower to sound of keycaps hitting the top of the switch housing, you need to place something in-between. Generally this is done with either O-rings, landing pads or silencing clips.

O-rings are very easy to find for cheap. They come in different thicknesses and different hardnesses, usually designated in the Shore durometer A-scale. Higher number means harder and thus less mushy but more silent. The letter after the hardness scale denotes the thickness; L for 0.2mm and R for 0.4mm.

Landing pads and clips function in much the same way, with the added benefit of being a bit easier to install - clips even more so.

Landing pads are placed on top of the switch housing and act as a bumper between the switch and the keycap. They also come in different hardnesses and thicknesses so you can pick the option you like the most. Clips accomplish the same but are installed by clipping a plastic sleeve over the switches that has the bumper material at the top.

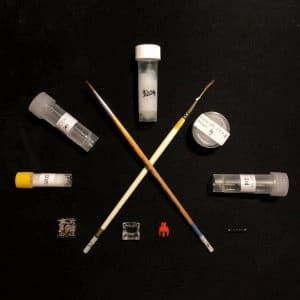

Lubricating switches

One very time-consuming step you can take is the lubricate all moving parts inside the switches and in the stabilizers that support larger keys. This is a time consuming process for which you need special lubricants and that warrants a separate guide on how to lube switches.

In short, there are 3 places to lubricate:

- switch sliders

- switch springs

- stabilizer contact points

The sliders can be lubricated with medium thick to light lubricant, while the stabilizer contact points best work with thicker grease-type substances. The springs function best when lightly oiled. In addition to removing the plastic-on-plastic rattle, lubing smoothens out the switch operation, resulting in a very fluid up and down motion.

Band-aid clipping mod

The band-aid clipping mod involves modifying the stabilizer keys. These are the additional faux switches on larger keys, such as the spacebar and right shift. The mod helps a lol to remove rattle from the metal bar that connects the stabilizers and dampens the sound produced from the stabilizer stem slamming against the PCB.

The mod usually involves the following changes:

- Clip the additional plastic feet from the stabilizer stem.

- Stick a band-aids underneath the stabilizers on the PCB.

- Add a lube or grease to the stabilizer metal bars.

The band-aid dampens impact from the stem slamming on the PCB and helps contain the lube/grease inside the housing, the clipping removes additional friction, and the lube/grease removes the rattle from the metal bar.

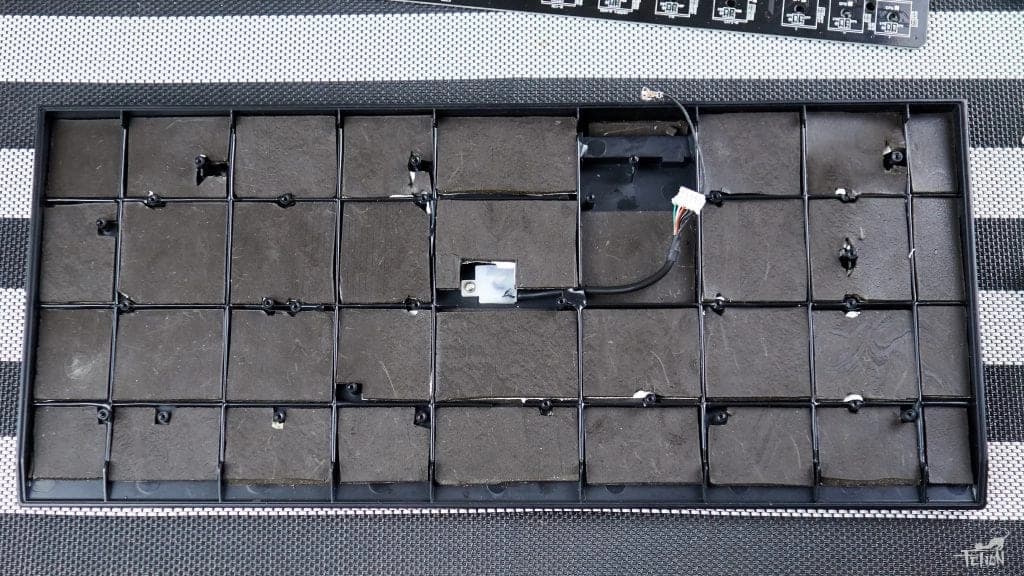

Dampening the case

Now that the keycaps and the switches are taken care of, we need to make sure the case isn't functioning as an echo chamber. To do this, you'll need to disassemble the keyboard. Pack the empty voids below the circuit board with something that is fairly dense and preferably heavy, but that still absorbs sound waves and vibrations.

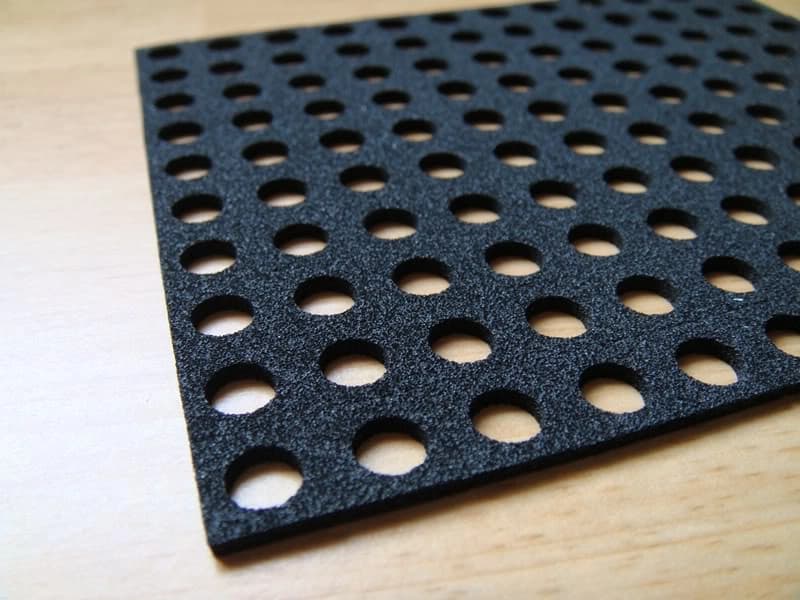

The best way to do this is to use bitumen sheets as vibration-absorbers and acoustic foam to kill the soundwaves themselves.

Stick bitumen at the bottom of the case, and lay acoustic foam on top, filling the voids completely. If you don't have bitumen and acoustic foam, you can use any type of foam to achieve 90% of the same benefits. You can even cast silicon inside to fill the voids.

In addition, you can see if there’s any additional screws in your case that you can leave out. Specifically the screws that go into the switch plate. This might not reduce the reverb but instead create a more uniform sound.

Dealing with the table

Last link in the chain; the table. Quite frankly, there aren't many things you can do to the table itself. An echoey table will be an echoey table - there's no way around that.

However, you can place something in-between the table and the keyboard to reduce the amount of vibrations traveling from your fingers to the table.

A small towel works fine, but doesn't look very nice. A better option is a desk-wide mousepad that also reaches under your keyboard. These so-called deskmats also look clean and provide a ton of mouse space. Vibrations from the keyboard to the table are reduced significantly, and the looks of your setup are increased. Win-win!

Master of silence

Each keyboard design has its own unique sound signature, hate it or love it, but you can always dampen the sound. The quickest method is to place a tower underneath it and install o-rings. When you’re up to the challenge, you can open the case to fill up the echo chambers, start lubricating switches, and band-aid clip those stabilizer keys.